In an era of increasing resource scarcity, the circular economy has become a critical global development direction. Its goal is to minimise resource waste and enable continuous material recycling. Recyclable PP non-woven honeycomb panels are an ideal material for achieving this objective.

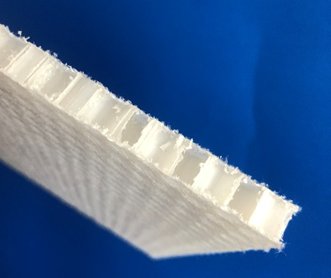

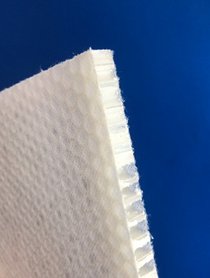

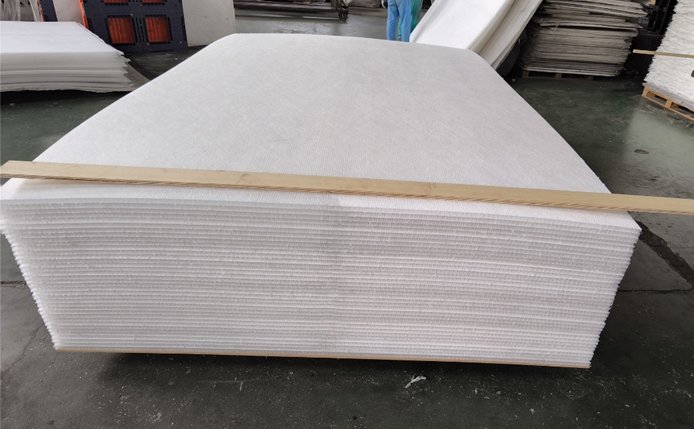

Achieving PP/Plastic Honeycomb panels mimic the structure of a beehive, consisting of two non-woven surface layers and PP honeycomb core material in between. This design gives them the characteristics of being "light, strong, and stable," making them widely applicable in the marine industry, automotive manufacturing, and construction.

Unlike traditional materials, recyclable honeycomb panels are made from thermoplastic plastics (such as polypropylene) and eco-friendly adhesives. These materials can be melted and reshaped through heating during recycling, truly achieving a "cradle-to-cradle" cycle.

1. Reduction (Reduce)

The lightweight nature of honeycomb panels significantly reduces energy consumption during transportation. For example, using them in automotive manufacturing can lessen vehicle weight, thereby reducing fuel consumption and carbon emissions.

2. Reuse

The material is durable and has a long lifespan. Even if a component is damaged, it can be easily repaired or refurbished, extending its overall usage cycle.

3. Recycling

At the end of their life cycle, the products can be broken down and melted through simple processes to regenerate new materials. These can be used to manufacture new honeycomb panels or other products, avoiding resource waste and environmental pollution while creating a closed-loop cycle.

4. Energy Savings and Emission Reduction

The entire lifecycle of recyclable honeycomb panels—from production to recycling—generates far fewer carbon emissions compared to traditional materials, helping businesses achieve their green transition.

Currently, recyclable honeycomb panels are used in automotive interiors, the marine industry, and architectural partitions. As technology advances, they will increasingly integrate with bio-based materials, further reducing reliance on fossil resources.

Achieving PP plastic Recyclable honeycomb panels are not only a high-performing but also a practical implementation of the circular economy. They make "green" lighter, stronger, and more sustainable, offering an effective path toward a future of resource recycling.