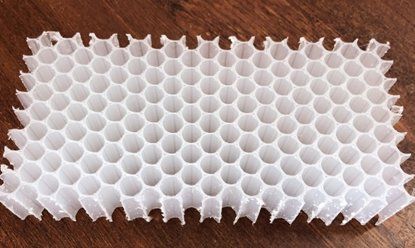

In waterjet cutting, the PP honeycomb board, with honeycomb structure and polypropylene (PP) material, has become a revolutionary alternative to traditional cutting pads. It addresses issues such as drainage, shock absorption, and cost, enabling efficient and eco-friendly industrial manufacturing.

Core Advantages

1. Honeycomb Structure: Swift Drainage, No Collapse

The circular-hole honeycomb perforations enable instant drainage of wastewater and debris. Lab tests show a 70% higher drainage efficiency than solid plastic boards, with 50% drier cutting surfaces, significantly reducing corrosion risks.

2. Flexible Shock Absorption: Protects Equipment

The elasticity of the PP material, combined with the honeycomb structure's energy-dispersing ability, absorbs over 90% of the waterjet impact energy. The service life of the cutting head can be extended by 30%, and the noise can be reduced to below 75 decibels.

3. Lightweight & Strong: Half the Weight, Double the Strength

Traditional steel pads weigh 30kg/m², while PP honeycomb boards weigh only 15kg/m² but achieve compressive strength over 8MPa, easily supporting multi-ton workpieces. Workers note improved handling efficiency and less back strain.

4. Eco-Friendly & Cost-Effective

PP material is 100% recyclable. Each board has a 2 - 3 year service life and 40% lower maintenance costs. Replacing 10% of the world's waterjet cutting pads with PP honeycomb boards can reduce more than 5,000 tons of plastic waste annually.

Adaptability Across Industries

The PP honeycomb board is excellent for various applications:

Stone/Metal Cutting: Rapid debris removal stops surface scratches.

Composite Materials (Carbon Fibre, Fibreglass): Elastic buffering prevents edge delamination.

Food/Medical Equipment: Non-toxic, corrosion-resistant PP meets hygienic standards.

Precision Engraving & High-Frequency Production: High flatness and lightweight design boost accuracy and efficiency while cutting long-term costs.

Our Expertise

We specialise in PP plastic honeycomb solutions, and our products possess a series of outstanding features. Our products can be highly customised, featuring high-strength boards and high surface flatness, while also being lightweight and durable.

Our boards are made of corrosion-resistant and environmentally friendly PP materials. These materials not only can effectively reduce vibration and noise, providing a buffering effect, but also can extend the service life of the equipment. The sizes can be customised to perfectly match all waterjet cutting systems, making them ideal for stone, metal, composite materials, and precision machining.

If you have any needs, you are welcome to contact us for consultation via Email: info@cnhoneycomb.com.